About our approaches to safety and security

3 principles for quality management

We hold three basic principles exploit by TQM as below.

◇The places to produce

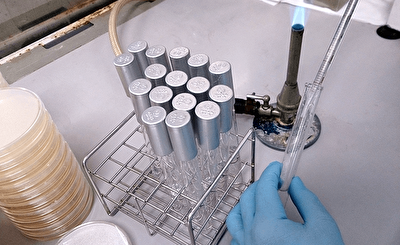

- ◇Maintenance and Management of its environment conducted by HACCP system

- ◇Environment of producing sanitation-checked regularly

◇Production line introduced by the latest equipment and machineries

◇Maintenance and inspection of equipment manufacturer

◇Measures of illuminating vermin conducted by the specialists

◇Management of the temperature of factories

◇Setting up some security cameras watching manufacturing line

◇Producer to manage the health and safety for workers

-

- ◇Checking workers’ temperatures before entering the inside

- ◇Checking by metal detector

◇Conducting 3 types of stool tests

・a normal stool test

・a stool test for world passengers

・Norovirus test

◇Distinction management for requiring injured people to wear masks

◇Washing hands with isodine holding the power to prevent from norovirus

◇Checking the sanitation after washing hands

◇Wearing two gloves after washing hands

◇Productions to make

- ◇Checking the factories producing the ingredients

◇Checking producing districts and qualities of ingredients regularly

◇Setting up durable life of new productions with both scientific and rational grounds

◇Checking the quality of productions ( microbe tests, physics and chemistry tests and sensual tests)

◇A spot checking of ingredients and manufacturing line

◇Appropriate indicators holding the latest legal information